Quality control

Quality First

In Coretech Flow, we firmly believe in "Quality First" because our team understands our valves could be used in most severe conditions and the stake is high for our end users and environment. And we also believe the top-notch quality is maintained through stringent procedures not the human interactions. That's why we established vigorous testing procedures from vendor selection, raw material receipt all the way through final assembly testing to identify non-conformance as early as possible. Catching a defect on our shop floor before finished goods' leaving our dock is essential for quality management. Quality is our core value and commitment to our demanding customers in today's demanding global marketplace.

The scope of our quality management system covers all processes directly and indirectly related to the design, manufacture, assembly, and test of our valves. Our goal is to deliver the highest possible quality at a competitive price.

non-Destructive test

NDT

Non-destructive testing (NDT) is a wide group of analysis techniques used in the industry to evaluate the properties of a material or component without causing damage. Commonly utilized NDT methods include ultrasonic test (UT), magnetic-particle(MT), liquid penetrant (PT), and radiographic (RT). Other than outsourced RT, our companies have in-house capabilities to do all these tests to ensure the integrity of materials and components before integration to a valve.

Ultrasonic Test (UT)

UT is a testing technique based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws of pressure containing parts or welding joints.

Magnetic Particle (MT) Test

MT is utilized for defects on and slightly below the valve surface. For quick, low-cost inspections, MT is often the best NDT method for detecting surface and slightly subsurface discontinuities.

Metallurgy Test

Metallographic analysis is the study of the physical structure and components of metals, typically using microscopy to analyze properties of forged alloy. The surface of a metallographic specimen is prepared by various methods of grinding, polishing, and etching. After preparation, it is often analyzed using optical or electron microscopy. Using. only metallographic techniques, a skilled technician can identify alloys and predict material properties.

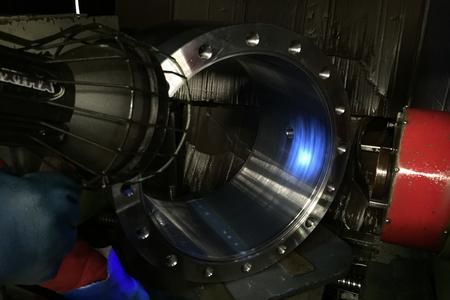

Fire Test

The test consists of selected valves to a flame of specific thermal power (jet fire) for a specified period (typically 30 or 120 minutes). The integrity of the component at the end of the test indicates that the test itself has been passed. The relevant governing specification is the API6FA. The wide range of Master Valve products is fire-safe to meet customers' requirements on safer plant operating environment.

Charpy impact test

The Charpy impact test, also known as the Charpy V-notch test, is a standard high strain-rate test which determines the amount of energy absorbed by a material during fracture.

This absorbed energy is a measure of a given material's notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition. It is widely applied in valve industry for low temp applications.

Low emission test

Valves and pipes are identified as the single largest source of green house gas emission in process plants.

More and more end users demand low emission test results to meet their commitment and responsibility to maintain a safer and more environment-friendly operations in their plants.

TA-LUFT and lSO 15848 are popular testing standards for the industry.

positive material identification

Positive Material Identification (PMI) is the identification and chemical analysis of various metal alloys through nondestructive methods. PMI can be conducted on-site or in the laboratory. PMI is done by using reliable portable analyzers, allowing the following tasks accomplished:

- Incoming inspection of alloy materials and components before they enter production

- Rapid verification of alloys used in the manufacturing process

- Product material confirmation before shipment